/ synthetic rubber

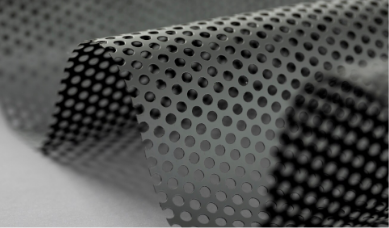

GRP’s Synthetic Rubber Reclaim business focuses on converting end-of-life synthetic rubber - such as butyl and EPDM - into

high-quality

reclaimed rubber through environmentally responsible processes. These reclaims retain

strong

vulcanization properties and are REACH

compliant, offering manufacturers a cost-effective and sustainable

alternative to virgin rubber

without compromising on performance.

Used across automotive, construction, and consumer industries, GRP’s synthetic reclaims are valued

for their ease of processing, faster mixing, and reduced energy consumption. Applications range from

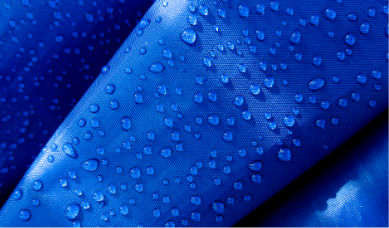

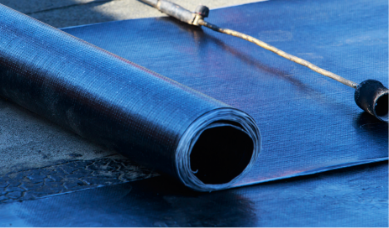

inner tubes and tyre liners to roofing membranes, cable insulation, and molded goods—helping

customers reduce costs while supporting circular economy goals.

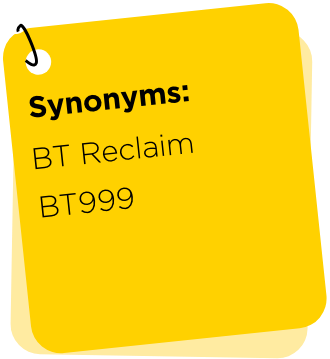

GRP’s Butyl Reclaim is manufactured from used butyl tubes, processed through advanced recovery techniques to ensure high-quality output. Known for its superior vulcanisation properties, this reclaimed material delivers consistent performance, making it a dependable choice for a wide range of rubber applications.

By offering a sustainable and cost-effective alternative to virgin butyl, GRP’s Butyl Reclaim supports both environmental responsibility and manufacturing efficiency—without compromising on quality.

Whether you’re optimising formulations or seeking greener material solutions, GRP’s Butyl Reclaim is engineered to meet your performance and sustainability goals.

In Butyl Reclaim, GRP has 2 grades:

Reduced Power Consumption due to nerve of compound

Practically no reduction in hot air ageing properties

Increases scorch safetyof compound

Improved Die swell

Faster Mixing Cycle

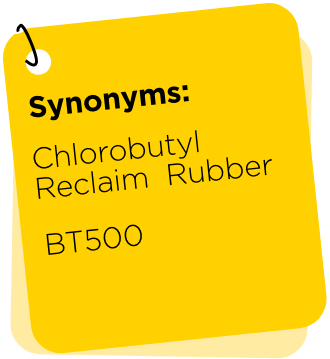

GRP Chlorobutyl Reclaim is a high-performance reclaimed rubber produced from used chlorobutyl tubes through a sustainable recycling process, offering excellent vulcanization properties that make it a reliable and eco-friendly choice for diverse rubber compounding applications. It features good adhesive properties and compatibility with other rubbers, improved extrusion quality and rate for better dimensional control, superfine grain size with uniform dusting. It is REACH compliant, ensuring it meets global safety and environmental standards .

In Chlorobutyl Reclaim, GRP has 1 grade:

Reduced Power Consumption due to nerve of compound

Practically no reduction in hot air ageing properties

Increases scorch safetyof compound

Improved Die swell

Faster Mixing Cycle

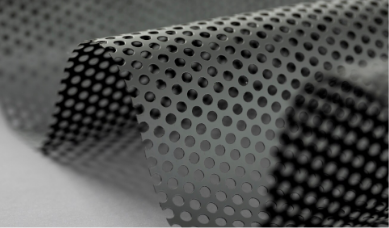

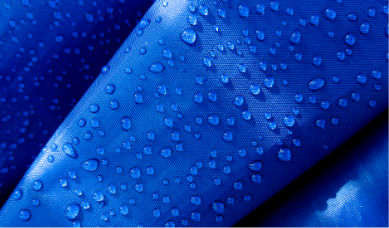

At GRP, we offer high-quality EPDM Reclaim, engineered from factory-reject EPDM profiles through a meticulous recovery process. This sustainable material is trusted across a wide spectrum of industries, serving both general-purpose and speciality applications with consistent reliability.

Our EPDM Reclaim retains excellent vulcanisation properties, ensuring smooth processing and dependable performance in end-use applications. It stands out as a cost-effective alternative to virgin EPDM, helping manufacturers reduce material costs without compromising on quality or functionality

Whether you're looking to enhance your product's sustainability profile or optimise your production economics, GRP’s EPDM Reclaim delivers the ideal balance of performance, processability, and environmental responsibility.

In EPDM Reclaim, GRP has 2 grades:

Reduced Power Consumption due to nerve of compound

Practically no reduction in hot air ageing properties

Increases scorch safetyof compound

Improved Die swell

Faster Mixing Cycle

Application: PHR*

Butyl Inner Tubes

Tyre Inner Liner

Adhesives

Cable Beading Compound

Sound Dampener

Water Proofing Sheets

*Based on GRP Formulary / GRP Internal Working / Customer Feedback

Used across automotive, construction, and consumer industries, GRP’s synthetic reclaims are valued for their ease of processing, faster mixing, and reduced energy consumption. Applications range from inner tubes and tyre liners to roofing membranes, cable insulation, and molded goods - helping customers reduce costs while supporting circular economy goals.