/ polycoat

POLYCOAT is a high-performance elastic powder in compounded form, produced through specialised treatment of ground waste rubber. Designed to deliver superior performance and consistency, it serves as an innovative solution for select applications.

Polycoat is a pre-compounded rubber additive made from specially treated waste rubber. It’s designed to improve the performance of rubber compounds by enhancing dispersion, reducing air entrapment, and simplifying the mixing process. Available in Natural and Nitrile grades, Polycoat blends quickly and easily into existing formulations, saving time, energy, and cost.

By replacing part of the virgin polymer, Polycoat helps manufacturers reduce compound costs by up to 20% without compromising quality. It’s ideal for a wide range of rubber applications and supports more sustainable production practices.

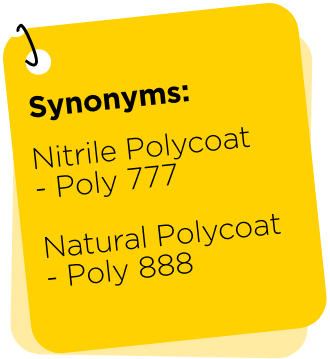

In POLYCOAT, GRP has 2 grades:

First mix the compound stock including curatives and then simply add POLYCOAT for quick blending. It will need less than 3 minutes for complete dispersion/blending of Polycoat and the compound. Polycoat may be used up to 30% of total compound, after addition of accelerator and sulfur. To get optimum result, use the Polycoat within 3 months of production.

Faster mixing cycle

Improved dispersion

Self curing

Improved air venting

Lower compound cost

Renowned for its excellent process-ability and consistent quality, GRP’s Natural Reclaim enhances compound properties across a wide range of applications. From tyres and footwear to automotive components, mats, and various non-tyre products, it empowers industries to meet both technical and sustainability goals.

By choosing GRP’s Natural Reclaim Rubber, you’re not just improving your product—you’re contributing to a circular economy and a more sustainable future.