/ tyre applications

GRP’s Rubber plays a vital role in enhancing the performance and sustainability of tyre manufacturing. Derived from end-of-life tyres and processed to meet stringent quality standards, our reclaim rubber improves compound flexibility, reduces production costs, and supports eco-friendly formulations. +More

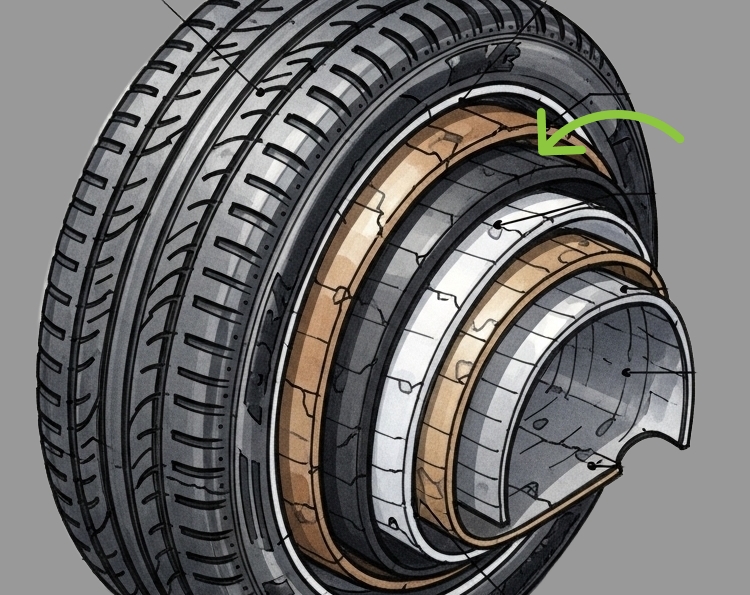

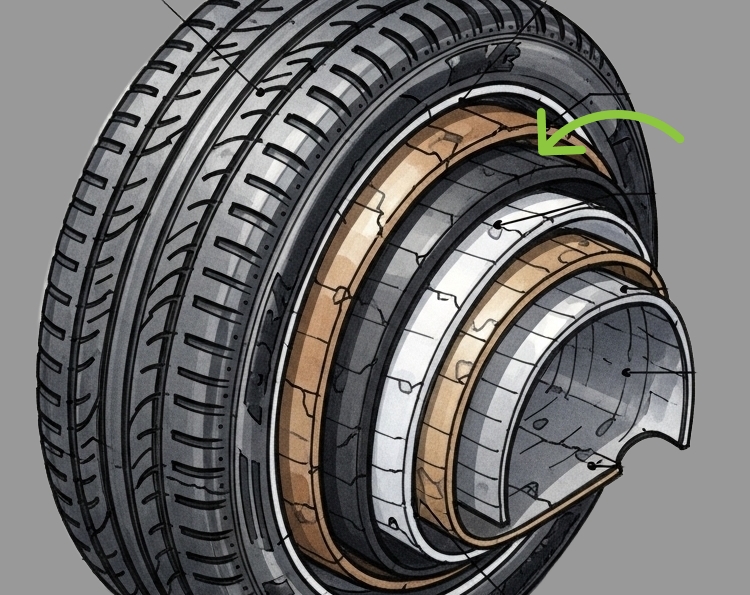

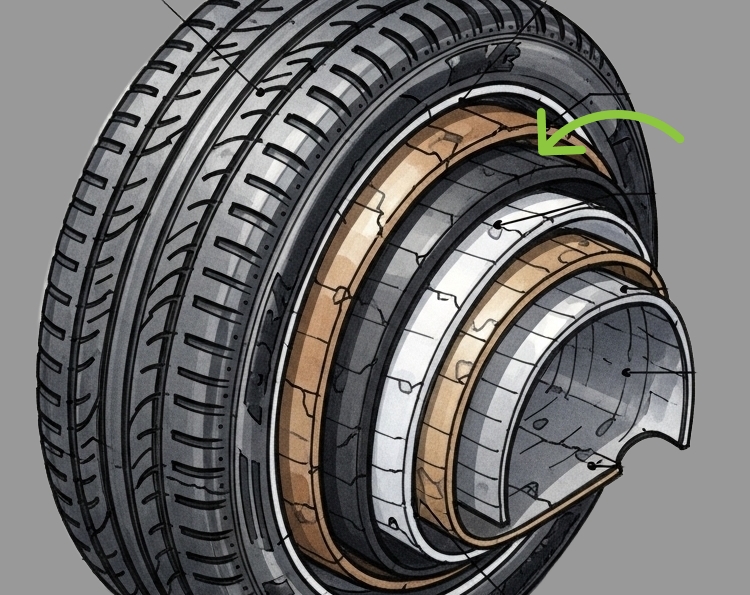

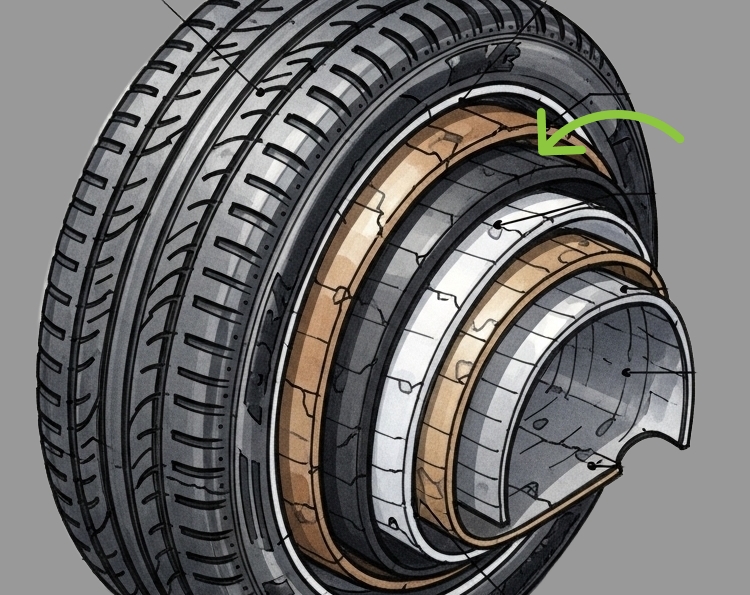

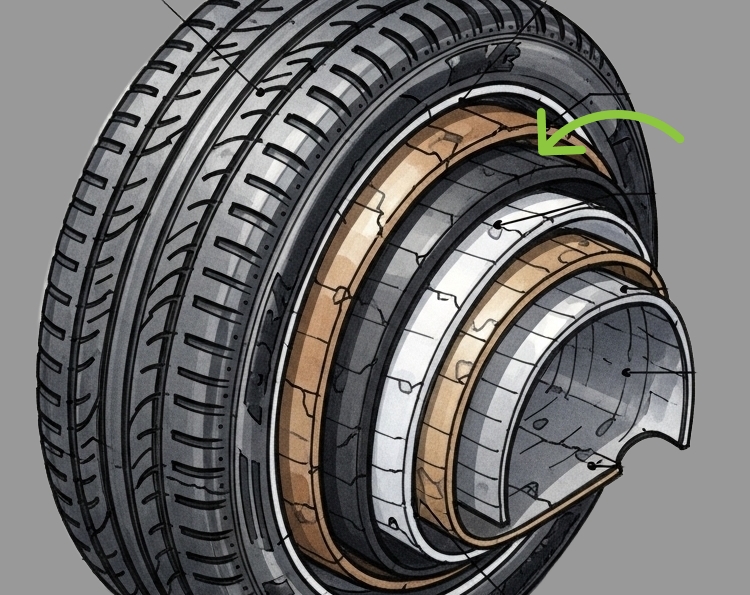

The inner liner is a rubber compound bonded to the inside of the cord body that retains air under pressure. It has no cord reinforcing and function as an inner tube in a tubeless tire

It is extruded Butyl or Halobutyl rubber sheet compounded with rubber additives. A key property of inner liner is low air permeability as it functions as inner tube.

A typical Inner Liner formulation contains a Butyl Rubber / Halobutyl Rubber and Reclaim Rubber.

Inner liner compounds are formulated to minimize permeation of air through the tire carcass. Compound properties and gauges (thickness) as well as the temperature and inflation pressureimpact on the permeation rate.

BUTYL RECLAIM

CHLOROBUTYL RECLAIM

Compared to other grades of Reclaimed Rubber there is low air permeability

Less masticating with easy incorporation

Improved Extrusion Quality & Rate with better control on Dimensions

Good tack in compound

Reduction in splicing defects

Reduced Power Consumption

Inner tubes are torus-shaped balloons made from an impermeable material, such as Butyl Rubber or Chlorobutyl Rubber. The inner tubes are inserted into the tire and inflated to retain air pressure.

Auto tubes are manufactured by molding method. Mixed compounded rubber is fed into the extruder and the rubber compound takes the shape of

long tubes then proper length of this green tube is cut and tube valve is fitted in this green tube and the end of the tubes are jointed by means of butt joining machine. This green tube is vulcanized in the mould having air pressure inside.

A typical Inner Tube formulation contains a Butyl Rubber or Chlorobutyl Rubber and Butyl/ Chlorobutyl Reclaim Rubber.

BUTYL RECLAIM

CHLOROBUTYL RECLAIM

Compared to other grades of Reclaimed Rubber there is low air permeability

Less masticating with easy incorporation

Improved Extrusion Quality & Rate with better control on Dimensions

Good tack in compound

Reduction in splicing defects

Reduced Power Consumption

The sidewall is the area of a tire from the bead to the tread. It forms a protective covering for the cord body.

Sidewall rubber compounds resist aging, cracking, cutting, and snagging.Tire sidewall rubber serves to protect the body plies from abrasion, impact and flex fatigue. The rubber compound is formulated to resist cracking due to environmental hazards such as ozone, oxygen, UV radiation and heat.

The sidewalls also carry decorative treatments, sometimes including white or colored stripes or letters.

A typical sidewall formulation contains a blend of Natural Rubber, Butadiene Rubber and Reclaim Rubber.

Whole Tyre Reclaim

Ultra High & High Tensile Reclaim

Good resistance to flex fatigue

Better abrasion resistance

Better Tensile Strength and Elongation %

Energy efficiency while mixing

The body is made up of several layers of different fabrics coated with Rubber called plies. Rubber coated cord, called body plies, make up the cord body. The cord body provides tyre strength and transmits cornering forces from the tread to the wheel. Belt plies are two or more strong layers of cord under the tread area. The cap ply also found in some tires is similar to belt edge strips only full width instead of just on the belt edges.

In textile reinforcements of nylon, polyester, rayon, aramid, etc., individual filaments are twisted and cabled together to form cords.

A typical Inner Liner formulation contains a Natural Rubber and Reclaim Rubber.

Whole Tyre Reclaim

Ultra High & High Tensile Reclaim

Good tack properties

Better Tensile Strength and Elongation %

Better abrasion resistance

Better ageing properties

Good scorch safety

The tread is the portion of the tyre in contact with the road surface.

Tyre tread shape, grooves (pattern) and compound are designed to optimize the wear, traction, handling, fuel economy, and cut resistance characteristics of the tyre.

A typical tread formulation contains a blend of Natural Rubber,Styrene Butadiene Rubber and Reclaim Rubber.

Whole Tyre Reclaim

Ultra High & High Tensile Reclaim

Better Tensile Strength and Elongation %

Better abrasion resistance

Better ageing properties

Better scorch safety

Good Tear resistance

Energy efficiency while mixing