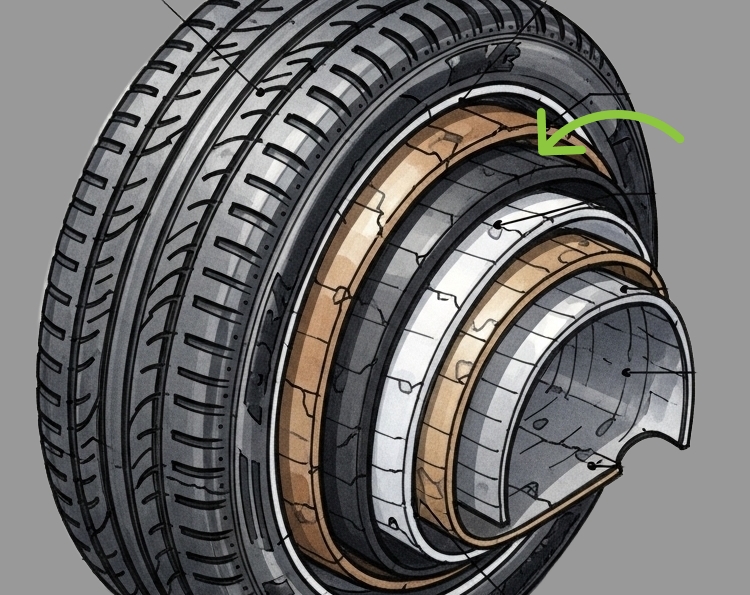

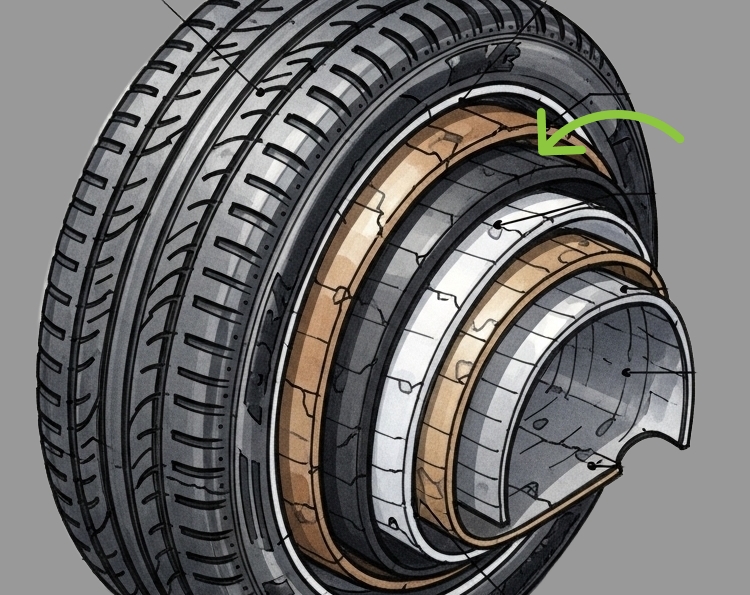

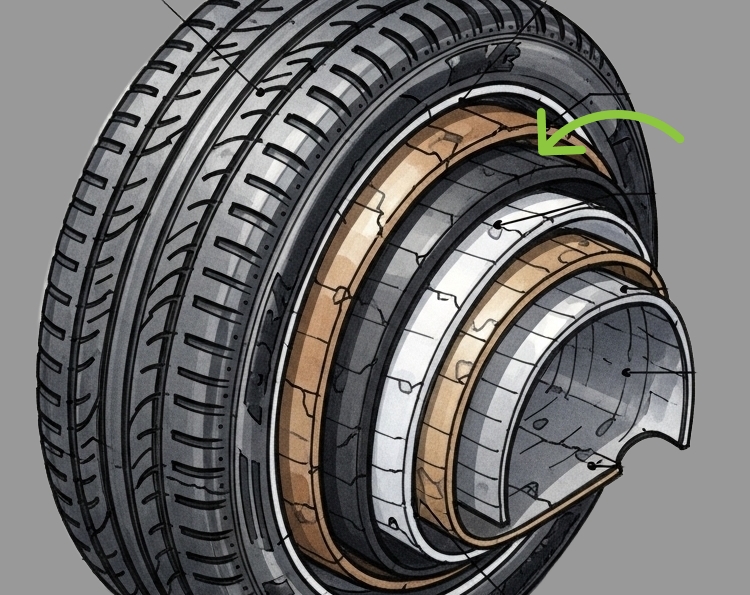

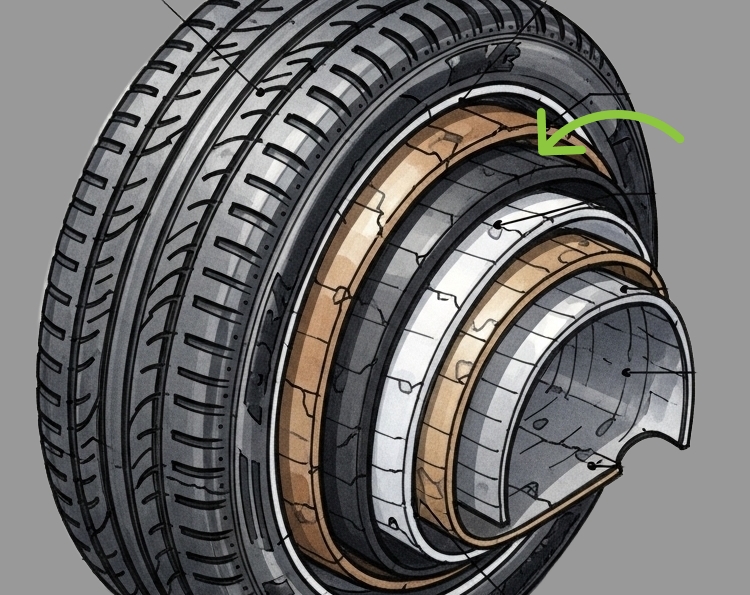

/ non tyre applications

GRP’s Natural Reclaim Rubber is produced from end-of-life tyres and tread peelings, transforming waste into a valuable resource. It is a reliable and cost-effective alternative to virgin rubber, helping manufacturers reduce raw material costs. +More

Conveyor belt is a continuous moving band used for transporting objects from one place to another. It is made of fabric, rubber, or metal.

Generally, the conveyor belt consists of one or more rubberized fabric layers of material. Polyester, nylon and cotton are the most common carcass materials. Top layer is called the cover, and under layer of material is called as carcass that provides linear strength and shape.

There are various types of conveyor belts available in the market. Most common are general purpose conveyor belt, oil resistance belts, energy saving belts, fire resistance belts, chemical resistance belts etc.

A typical conveyor belt formulation contains a blend of Natural Rubber, Styrene Butadiene Rubber and Reclaim Rubber.

Whole Tyre Reclaim

Ultra High & High Tensile Reclaim

Better Tensile Strength and Elongation %

Good scorch safety in High Tensile Reclaims

Better abrasion resistance

Good ageing properties

Good resistance to flex fatigue

For belts using EPDM, GRP EP101 is a recommended grade

Rubber compound material is placed into a heated metal mold, then is softened by the heat, and forced to conform to the shape of the mold as the mold closes. By temperature and pressure, it becomes vulcanized molded product.

In Rubber Industries various Rubber products are manufacturing by Molding. Molding can be done by Compression Molding, Transfer Molding or Injection Molding process.

A typical molded product formulation Natural Rubber, Butadiene Rubber, EPDM Rubber, Butyl Rubber, Chlorobutyl Rubber, Nitrile Rubber etc. GRP Reclaim Rubber and Polycoat is very useful in Molded products.

Whole Tyre Reclaim

Ultra High & High Tensile Reclaim

EPDM Reclaim

Butyl Reclaim

Chlorobutyl Reclaim

Polycoat (Nitrile)

Polycoat (Natural)

Better Tensile Strength and Elongation %

Good scorch safety in High Tensile Reclaims

Better abrasion resistance

Good ageing properties

Good resistance to flex fatigue

Note: For suitable formulations, please contact us. We will help you with your specific requirements and provide recommended formulations.

Adhesives are used to binds two materials together and resist their separation. The use of adhesives offers many advantages such as sewing, mechanical fastening, thermal bonding etc. It gives cost effectiveness as easily mechanized process. Key properties required in Adhesives are, it should able to wet the substrate & must harden with time.

There are many types of adhesives such as Drying adhesives, Pressure-sensitive adhesives, Contact adhesives, hot adhesives etc.

A typical applications of adhesives are Structural, Industrial, Packaging, Electrical & Electronics, Laboratory, aerospace etc.

A typical Adhesive formulation contains a blend of Butyl Rubber, Chlorobutyl Rubber and Reclaim Rubber.

Butyl Reclaim

Chlorobutyl Reclaim

Better tackiness

Easily compatible & Homogeneous mixing with virgin polymers

Smooth finish, which gives good bonding strength and resistance to separation of two materials

Better physical properties

Better ageing properties

Note: For suitable formulations, please contact us. We will help you with your specific requirements and provide recommended formulations.

Footwear gives the protection to the feet against heat, cold, dampness, dirt or roughness of the ground. Currently footwear is a part of fashion. In the market many types and fashionable footwearare available. Some examples are boots, shoes sandals, Sports footwear, specific purpose footwear, household footwear and traditional footwear.

Generally, footwear is made of Rubber, leather, plastic and fabric.

Key properties required in footwear are good strength, good abrasion resistance,

weather resistance, softness, aesthetic look.

A typical Footwear formulation contains Natural Rubber, Styrene Butadiene Rubber, EPDM Rubber and Reclaim Rubber.

Whole Tyre Reclaim

Ultra High & High Tensile Reclaim

EPDM Reclaim

Better Tensile Strength and Elongation %

Good scorch safety in High Tensile Reclaims

Better abrasion resistance

Reduce mixing time

Good resistance to flex fatigue

Note: For suitable formulations, please contact us. We will help you with your specific requirements and provide recommended formulations.

Now a days Rubber flooring is in demand. Rubber Matting is a new concept for house hold and industrial applications because of many advantages over conventional mattings.

A typical mattings formulation contains a Natural Rubber, Styrene Butadiene Rubber, EPDM Rubber and Reclaim Rubber. Rubber matting gives

Whole Tyre Reclaim

Ultra High & High Tensile Reclaim

EPDM Reclaim

Better Tensile Strength and Elongation %

Good scorch safety in High Tensile Reclaims

Better abrasion resistance

Reduce mixing time

Good resistance to flex fatigue

Note: For suitable formulations, please contact us. We will help you with your specific requirements and provide recommended formulations.

Rubber profiles are generally made from Extrusion process. Such rubber profiles majorly used in Automobile parts.

A typical profile formulation contains a blend of EPDM Rubber and Reclaim Rubber. Key properties required in profiles are good heat, ozone & weather resistance, smooth surface finish, crack resistance etc.

EPDM Reclaim

Smooth surface finish

Good heat, ozone, and weather resistance

Replaces virgin EPDM & helps in reduction of compound cost

Faster Mixing & Extrusion

Reduced energy consumption

Absence of blemishes consistent splice strength

Good cost effective compound

Note: For suitable formulations, please contact us. We will help you with your specific requirements and provide recommended formulations.

Rubber roofing is the most popular roofing system in US and Canadian market..

A typical Roofing formulation contains a mainly EPDM Rubber. Some manufacturers also prefer Butyl Rubber.

Butyl Reclaim

EPDM Reclaim

Good whether resistance

Water resistance

Reduces compound cost

Good compatibility with virgin Polymer

Note: For suitable formulations, please contact us. We will help you with your specific requirements and provide recommended formulations.