Since 2014, GRP has pioneered the recycling of polyamide from end-of-life tyres in India. Our Engineering Plastics division manufactures high-performance Nylon 6, Nylon 66, and PBT - leveraging inter-unit synergies and upcycled raw materials to replace 3000 MT of virgin polymers annually. Every product is rigorously tested and certified to meet demanding engineering standards.

GRP’s repurposed Nylon 6 compounds, both unfilled and glass- filled, are produced from recycled polyamide sources such as tyre cords, processing wastes and ocean wastes. The unfilled grade offers excellent impact resistance, wear properties, and ease of processing. The glass- filled grade, with up to 50% glass fiber, delivers enhanced tensile strength, stiffness, thermal stability, and dimensional accuracy. These sustainable compounds are engineered for automotive, electrical & electronics, and industrial applications requiring high performance and durability.

For applications requiring very high mechanical and thermal properties, Nylon 6 is reinforced in various combinations of reinforcing materials depending on the properties required and applications

Typical glass filled combinations includes 15% glass filled Nylon 6, 30% glass filled Nylon 6, 35% glass filled Nylon 6

Nylon 6 is a semi-crystalline synthetic polymer, produced from Polymerization of caprolactam. It is also known as Polyamide 6 or PA6 and has great demand due to its strength, high abrasion resistance, surface appearance and process-ability compared to Nylon66. Nylon 6 is used in various forms like prime polymer, reprocessed granules, scrap, lumps, modified Nylon 6 for high performance, blends & compound

High tensile and modulus

High heat deflection temperature

High creep resistance

Low moisture content

Cost-effective & sustainable solutions

Properties consistency

Renowned for its high-performance and sustainable innovation, GRP’s Engineering Plastics deliver consistent quality and process-ability across demanding applications. From automotive and electricals to consumer goods, our Nylon and PBT solutions help industries meet both technical excellence and environmental goals. By choosing GRP’s upcycled polymers, you’re not just enhancing your product—you’re driving the shift toward a circular economy and a greener future.

GRP’s repurposed Nylon 66 compounds, sourced from processing waste and discarded airbags, deliver high- performance, sustainable solutions. The unfilled grade offers excellent strength and chemical resistance, while the glass-filled variant (up to 30% GF) enhances tensile strength, stiffness, thermal stability, and dimensional accuracy.

Ideal for automotive, electrical, and industrial applications demanding durability, heat resistance, and consistent quality.

High tensile and modulus

High heat deflection temperature

High creep resistance

Low moisture content

Cost-effective & sustainable solutions

Properties consistency

Renowned for its high-performance and sustainable innovation, GRP’s Engineering Plastics deliver consistent quality and process-ability across demanding applications. From automotive and electricals to consumer goods, our Nylon and PBT solutions help industries meet both technical excellence and environmental goals. By choosing GRP’s upcycled polymers, you’re not just enhancing your product—you’re driving the shift toward a circular economy and a greener future.

GRP’s Repurposed Polyolefins business delivers sustainable, high-performance material solutions by upcycling end-of-life rigid polyolefin packaging waste.

Through advanced sorting and compounding processes, we convert discarded materials into raw materials with mechanical and processing properties comparable to virgin polyolefins.

These cvompounds are engineered for use in rigid packaging, furniture, automotive components, and as base polymers for compounding and masterbatch applications, supporting circularity without compromising on quality or consistency.

This is a new product by GRP:

Easy Access:

GRP has a strong / in-house sourcing network.

Capabilities:

GRP has strong process and product development capabilities

Applications:

Sustainable and circular material solution provider

PRODUCTS USED:

TPE

Impact copolymer PP (IC PP)

GLASS/TALC FILLED PP

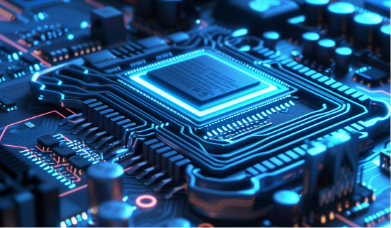

GRP’s repurposed PBT compounds, made from diverse feedstock, offer sustainable high-performance thermoplastics. The unfilled grade delivers excellent chemical resistance, dimensional stability, and electrical properties. Glass-filled (up to 30% GF) and mineral-filled variants enhance mechanical strength, stiffness, heat deflection, and surface finish. Ideal for automotive, electrical, and industrial applications demanding durability and consistent processing quality.

Ensuring Raw

Material Availability

Secure End-of-Life (EOL) raw material through pan-India sourcing.

Strengthen supply by partnering with brands, molders, and aggregators

Enhancing Sorting

& Cleaning Efficiency

Reduce rejections with stringent incoming quality checks at feedstock source

Improve process reliability through standardised screening methods

.png)

Driving Standard

Market Acceptance

Shift focus from restrictive colour choices to new application development

Promote use of off-white, grey, and black as sustainable industry standards